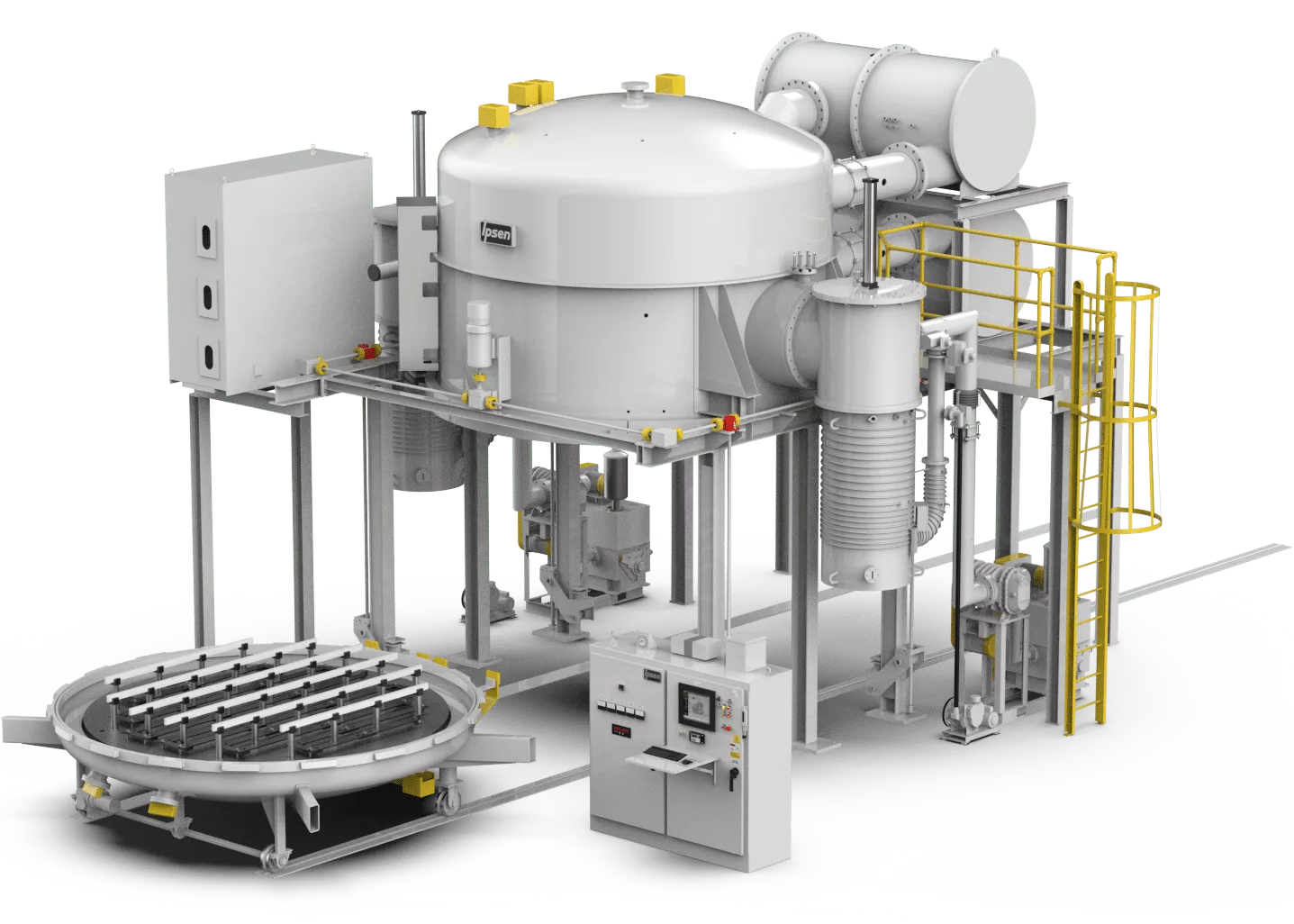

Vacuum Furnaces

Molecular-level precision. Repeatable processing.

We engineer our vacuum furnaces to achieve demanding specifications for your safety-critical and high-performance parts. Every Ipsen thermal processing solution is backed by expert support for the lifetime of your equipment.

Start Your QuoteFurnaces that strengthen your metals. A partnership that strengthens your business.

Furnace Specifications

Ipsen vacuum furnaces accommodate a wide range of heat treating processes, including:

- Annealing

- Brazing

- Carburizing

- Hardening

- Sintering

- Surface Treatments

- Tempering

Vacuum Aluminum Brazing (VAB)

All vacuum aluminum brazing furnaces feature individually controlled heating elements that surround the work zone, minimizing cycle times and providing precise, uniform heating of the workload. Joint-free heating elements eliminate resistance buildup and hot spots.

Solution Nitriding (SolNit®)

SolNit is a thermo-chemical heat treatment process similar to case hardening, but it uses nitrogen instead of carbon as an alloying agent. This process uses vacuum furnaces with high-pressure gas quenching capability for nitriding stainless steels, allowing low-grade stainless steel to be hardened for use in everything from surgical instruments to household appliances.

Vacuum Carburizing with Acetylene (AvaC®)

Our proprietary AvaC vacuum carburizing process uses acetylene to virtually eliminate the soot and tar formation problem known to occur from propane, while greatly increasing carburizing power even for blind or through holes. It ensures highly homogenous carburizing even for parts with complex geometries and high load densities.

Aluminum Ion Vapor Deposition (IVD)

Ion Vapor Deposition (IVD) is a process for applying pure aluminum coatings to parts for corrosion protection. To prevent oxygen and water vapor contamination, the aluminum coating is applied to the parts in a vacuum.

Debinding and Sintering

Vacuum debinding and sintering is a process used for powdered metal parts, MIM components, 3D metal printing, and beading applications. Parts are heated to the binding agent’s vaporization temperature and held at this level until all of the outgassing of the binding agent is complete. Then, the temperature is increased to the sintering temperature of the base alloy and held to ensure solid-state part diffusion occurs.

We produce our standard vacuum furnaces with tight temperature uniformity performance of ±10 °F (±6 °C), with high-temperature processing capability up to 3,000 °F (1,316 °C). Some furnace models, such as our Vacuum Aluminum Brazing line, can operate at ±5 °F (3 °C).

Graphite Hot Zones

Graphite hot zones are long-lasting and can deliver excellent ROI. They are robust, economical to repair and incorporate hearth designs with high creep strength.

All-Metal Molybdenum Hot Zones

If your process is susceptible to graphite contamination, a molybdenum hot zone can meet your needs. Our moly hot zone elements feature a “double-U” profile which makes them easy to install and replace.

Custom Constructions

We offer custom hot zone construction such as graphite insulation with moly heating elements, for applications with unique requirements.

Start Your Project

Expand your capacity. Add capabilities. Grow your business.

Reliable, precise, long-lasting vacuum solutions.

Blog Post

Choosing the Right Vacuum Furnace for Your Needs

Choosing the right furnace is critical for the success of your business and the quality of your parts – and there are a lot of choices available. When purchasing a…

Read More

Get in touch with a vacuum technology expert today.

We will help you maximize your next vacuum furnace investment so it brings the greatest possible value to your business. We start every solution with a full understanding of what you need to accomplish. Connect with us today.

Get Started