Ipsen Customer Service

Get the support you need for any brand of furnace, anywhere in the world, throughout your equipment’s entire lifecycle. When you need genuine replacement components, furnace modernization, immediate technical assistance and beyond, we are here to help.

Genuine Ipsen Components

Genuine Ipsen ComponentsQuickly get the parts you need with our dependable delivery, robust inventory and the help of our experienced customer service representatives. You can rest assured that the material, finish, tolerance, size and other details will be identical to the part being replaced – unless improvements are needed.

Browse Ipsen Components

- Loaders and unloaders

- Transfer devices

- Transportation devices

- Cross connectors

- Element connectors

- Element hanger assemblies

- Element supports

- Furnace seals

- Grafoil washers

- Graphite nuts

- Graphite-threaded rods

- Insulator washers

- Lip seals

- Moly nuts

- Moly retainer washers

- Moly-threaded rods (hangers)

- Vacuum gauge tubes

- Programmable logic controllers (PLCs)

- Relays

- Variable frequency drives

- Blower and pump oils

- Vacuum grease

- Burners

- Burner control units

- Burner tuning

- Burner safety

- Heating elements

- Fuses

- Insulators

- Power feedthroughs

- Pressure transducers

- Relays

- Thermocouples

- Thermocouple jacks

- Carbon sensor air pumps and probes

- Catalysts / Endo retorts

- Cylinder seal kits

- Fan blades and blade motors

- Fan insulation blocks

- Fan motors and motor bearings

- Furnace chain

- Diffusion pumps

- Dry/roughing pumps

- Holding pumps

- Mechanical/booster pumps

Service & Support

Service & SupportNo matter what brand, the age of your equipment, or your location in the world, Ipsen is here to keep you up and running smoothly.

Field Service

Our factory-trained and experienced Field Service Engineers provide support for vacuum and atmosphere furnaces worldwide. Some of our services include:

- Equipment installation services and relocation

- Extensive start-up testing

- Preventive maintenance packages

- Onsite repair, evaluation and support

- Major refurbishments

- Controls upgrades

- Onsite, offsite and virtual technical training

Technical Support

For technical support, warranty or start-up challenges, our Technical Support Team helps you resolve issues quickly so you can get back up and running. We offer:

- Phone support and troubleshooting

- Virtual remote support

- In-person start-up testing

- Wide network of experienced service engineers

- Help replacing warrantied products

Instrument Calibrations

Ipsen uses the Performance Review Institute’s methods and holds extensive pyrometry training. Our Field Service Engineers provide instrument calibration services and temperature uniformity surveys for vacuum and atmosphere furnaces that can adhere to strict AMS 2750 requirements. In the case we discover any nonconformances, our Field Service Engineers will make the necessary recommendations to get you back on track.

Experience World-Class Support

Find local support, Connect with an Ipsen expert or Request a quote:

Connect Start Your QuoteRetrofits, Rebuilds & Upgrades

Retrofits, Rebuilds & UpgradesGet the most out of your furnace with our modernization services. Bring your aged furnace back to life with custom retrofits, so you can run dependable, accurate processes for years to come.

RetrofitsEnhancing your furnace’s performance is easy when Ipsen’s experienced Retrofit Specialists work with you to determine your exact needs and deliver the right solution quickly. We offer retrofit packages for both vacuum and atmosphere furnaces that help you achieve precise sensing for greater control, better surface appearance, cycle time optimization or other specified requirements. Our technical sales staff can address your concerns and design the proper engineered solution for you. |

Rebuilds

Heat treating standards are constantly evolving, and by modernizing your equipment with a rebuild project, you can quickly bring it to a state-of-the-art condition without a major new investment.

The improved performance of your equipment will help increase productivity, ensure greater savings in terms of energy and resource consumption and provide improved transparency and operation when regulating and controlling the equipment. We can also help you retroactively automate your equipment, either partially or completely.

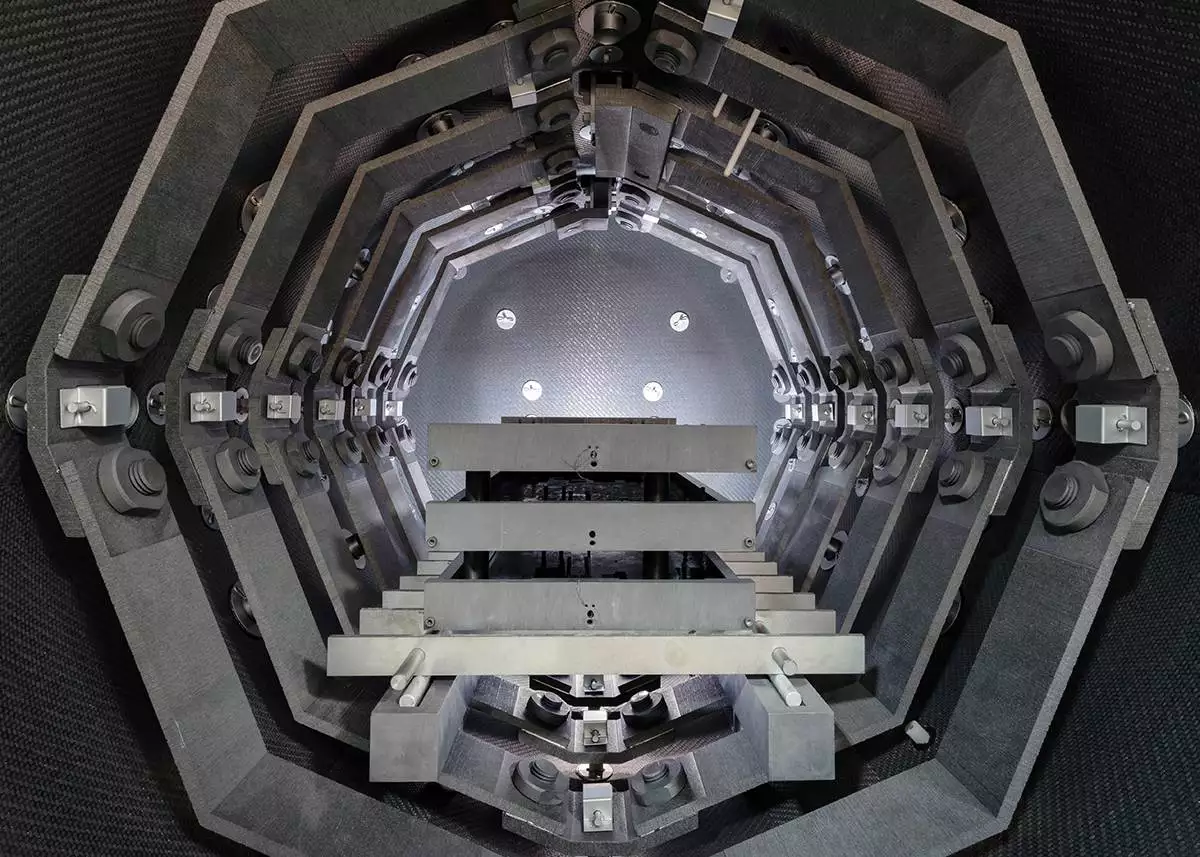

Furnace Insulation

When your insulation degrades over time, we can repair or replace it, bringing it back to its original condition. Our high-efficiency vacuum furnace hot zones and atmosphere refractories help maximize the performance of your furnace. Designed for easy installation and long-term reliability, our insulation options offer outstanding energy efficiency, uniform heating and cooling, and better temperature uniformity, resulting in faster processing and lower utility costs.

Electrical & Software

Proper control and functionality of your equipment are essential in thermal processing. Our engineers can help you optimize or modernize your electrical and software systems to achieve precise process control and better data collection and reporting, all while minimizing human error. Work with us so you can:

- Fine-tune your process with newer, more automated controls.

- Collect precise data to better measure and improve your process.

- Access the furnace through a SCADA system right from your desk.

How to Reach Us

Is something wrong with your equipment? Do you need technical support or spare parts? Call our customer service helpline to quickly connect with an Ipsen expert. View global customer service contacts

+1 844 Go Ipsen (+1 844 464 7736)

Toll Free